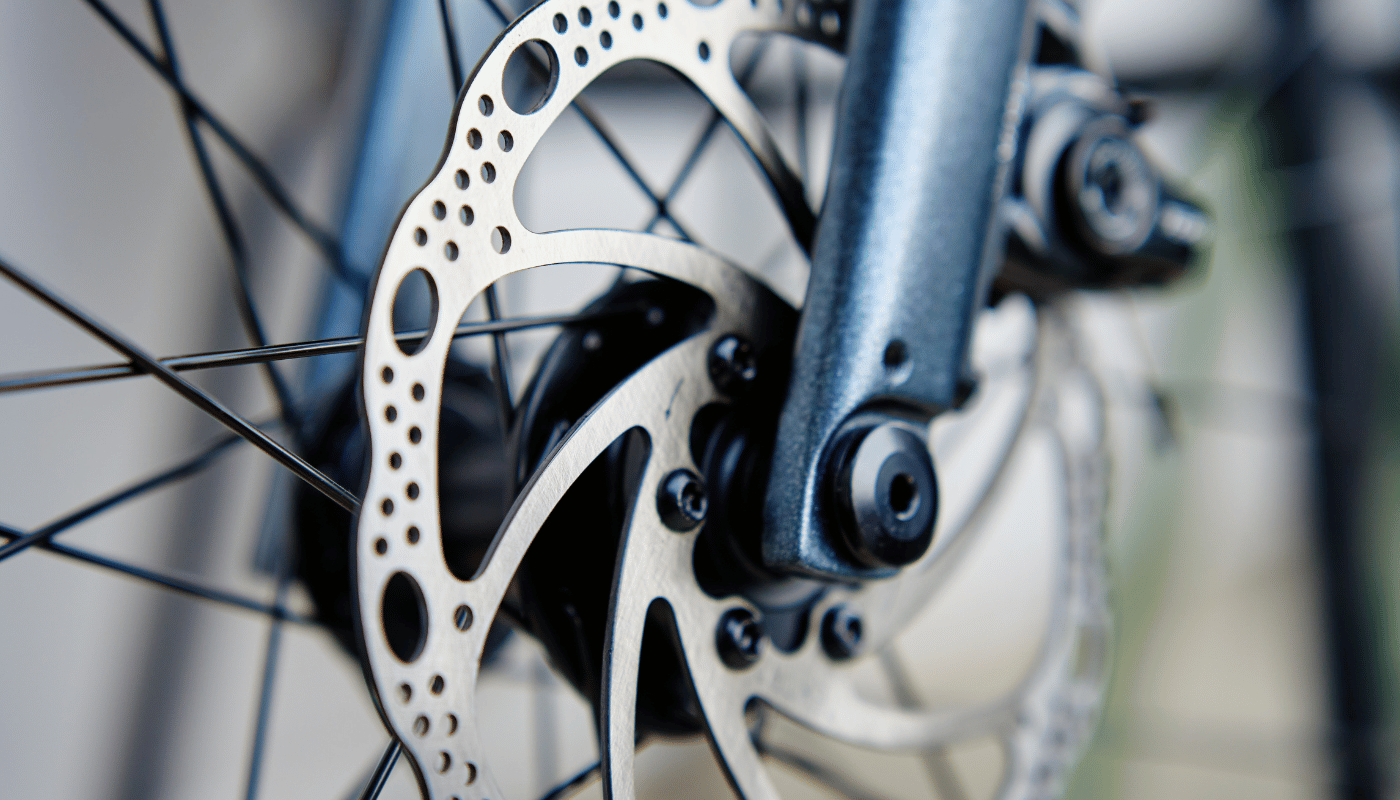

Ever experienced that high-pitched squeal from your bicycle brakes as you come to a stop? It’s not just annoying; it could be a sign of an underlying issue with your disc brakes. From wear and tear to alignment problems, several factors can contribute to this common cycling nuisance. In this article, we’ll explore the reasons behind squeaking bicycle disc brakes and offer solutions to ensure your rides are smooth and silent. Stay tuned to learn how to keep your stopping power effective and noise-free.

Common Causes of Squeaky Disc Brakes

The irritating squeak of disc brakes is a common issue that plagues many cyclists, both novice and experienced. This unwelcome noise can be attributed to a variety of factors, each affecting your ride’s comfort and your bike’s performance. Understanding these causes is the first step towards diagnosing and fixing the problem, ensuring a smoother, quieter ride.

One of the primary reasons for squeaky disc brakes is the presence of contaminants on the brake pads or rotors. These can range from oil and grease to mud and water, all of which interfere with the friction necessary for smooth braking. Another significant factor is misalignment; even a slight misalignment between the pads and rotors can lead to uneven wear and, consequently, noise. Additionally, wear and tear on the brake pads or rotors themselves can contribute to squeaking. Over time, pads can harden and lose their effectiveness, while rotors can develop surface irregularities, both of which can cause noise during braking.

Beyond these common causes, environmental conditions such as humidity and temperature can also play a role. In damp conditions, for example, a thin layer of rust can form on the rotors overnight, leading to a squeak until it’s worn off by the pads. Similarly, very high or low temperatures can affect the materials’ properties, sometimes resulting in squeaks. Understanding these factors is crucial for maintaining your bicycle’s disc brakes and ensuring a quiet, efficient braking system.

| Cause | Effect on Braking | Possible Solution |

|---|---|---|

| Contaminants | Reduced friction, noise | Clean pads and rotors |

| Misalignment | Uneven wear, noise | Adjust brake caliper position |

| Wear and Tear | Hardened pads, surface irregularities, noise | Replace pads or rotors |

| Environmental Conditions | Temporary rust, material property changes, noise | Regular maintenance and adjustments |

| Improper Bed-In | Insufficient pad-to-rotor adhesion, noise | Perform proper bed-in procedure |

Understanding the Causes of Squeaky Bicycle Disc Brakes

Bicycle disc brakes are a crucial component for safe cycling, offering superior stopping power in various weather conditions. However, encountering a squeaking noise each time you hit the brakes can be both annoying and concerning. This common issue can detract from your riding experience and signal underlying problems requiring attention. The primary causes of this undesirable noise include the presence of contaminants on the brake pads or disc, misalignment of the brake system, and the natural wear and tear of brake components.

Contaminants such as oil, dirt, or even small amounts of water can form a thin layer between the brake pad and the disc, leading to a squeaking sound during braking. These contaminants hinder the friction needed for effective stopping, causing the brakes to emit a high-pitched noise. Misalignment of the brake calipers or the disc itself can also result in uneven contact during braking, producing a squeal. Furthermore, the wear and tear of brake pads over time is inevitable. As the material on the pads wears down, it can reach a point where the metal backing plate comes into direct contact with the disc, leading to a loud squeaking noise. Regular maintenance and timely replacement of worn-out parts are essential to prevent this issue.

To mitigate the squeaking of bicycle disc brakes, consider the following steps:

- Clean the brake discs and pads regularly to remove any contaminants.

- Check for and correct any misalignment of the brake calipers and discs.

- Replace worn-out brake pads promptly before they completely wear down.

- Use only compatible brake pads and discs recommended by the manufacturer.

- Avoid exposing your bicycle to harsh chemicals or oils that could contaminate the braking system.

Understanding and addressing the causes of squeaky bicycle disc brakes not only enhances your riding experience but also ensures your safety on the road. Regular maintenance and proper care of the braking system play a pivotal role in preventing this common issue. By taking proactive steps to keep your bicycle in top condition, you can enjoy smooth and silent stops during every ride.

Cleaning and Maintenance Tips

Regular cleaning and maintenance of your bicycle’s disc brakes are crucial to ensure their optimal performance and to prevent that annoying squeaking sound when stopping. The accumulation of dirt, grime, and brake pad residue can significantly affect your brakes’ effectiveness and cause them to emit a high-pitched squeal. Here are some essential tips to keep your disc brakes in top condition.

Firstly, it’s important to clean your disc brakes regularly. Use a clean, lint-free cloth and isopropyl alcohol to wipe down the rotor surfaces gently. This removes any oily residues and contaminants that could cause squeaking. Secondly, inspect your brake pads for wear and tear. Worn-out pads not only reduce braking efficiency but can also damage the rotor if left unchecked. If the pads are thinner than 1.5mm, it’s time for a replacement. Lastly, ensure that the rotors are correctly aligned. Misalignment can lead to uneven wear and squeaking noises during braking. If necessary, adjust the caliper position to align the rotor properly within the brake pads.

Maintaining the right level of tightness on all bolts and fasteners is also crucial. Loose parts can lead to vibration, which contributes to noise. Make sure everything is secure, but be careful not to overtighten, as this can lead to other issues. Regular maintenance not only keeps your ride quiet but also extends the life of your brake components.

Advanced Techniques for Quieter Brakes

For those looking to delve deeper into disc brake maintenance, exploring advanced techniques can offer further benefits. Bedding in new brake pads, for instance, is a process that ensures even and smooth contact between the pads and rotors, reducing the likelihood of squeaking. This involves performing a series of controlled stops from a moderate speed without coming to a complete stop, then allowing the brakes to cool down. This process helps in achieving a uniform transfer layer, which can dramatically reduce noise and improve braking performance.

Understanding the Importance of Brake Fluid

Another aspect not to be overlooked is the condition of your brake fluid. Over time, brake fluid can absorb moisture, leading to reduced performance and potential brake failure. For hydraulic disc brakes, it’s advisable to bleed the system and replace the fluid according to the manufacturer’s recommendations. This ensures that your brakes remain responsive and efficient, providing peace of mind during your rides.

| Maintenance Task | Frequency | Importance |

|---|---|---|

| Cleaning Rotors | After every muddy ride or every month | High |

| Checking Pad Wear | Every 500 miles | Critical |

| Adjusting Caliper Position | As needed | Medium |

| Securing Bolts and Fasteners | Every service interval | High |

| Bleeding Hydraulic Lines | Annually or as performance dictates | Essential |

Adjusting Brake Pads and Calipers

Proper adjustment of brake pads and calipers is crucial to eliminate squeaking sounds from your bicycle disc brakes. This noise often results from the pads misaligning with the rotor, causing friction and, consequently, the irritating sound. Initially, check the alignment of the brake caliper to the rotor. Misalignment here can lead to uneven wear on the brake pads, which not only generates noise but can also reduce the efficiency of your braking system. Ensuring that your calipers are correctly aligned requires a careful adjustment process, often involving loosening the mounting bolts and repositioning the caliper so that the pads are equidistant from the rotor on both sides.

Another critical aspect to consider is the condition and positioning of the brake pads themselves. Over time, brake pads can wear down unevenly or become contaminated with dirt, oil, or other substances, all of which can cause squeaking. If the pads appear to be unevenly worn, it may be necessary to replace them. Additionally, make sure that the pads are correctly oriented; they should be parallel to the rotor and not touching it unless you are applying the brakes. Sometimes, a slight adjustment to the pad position can make a significant difference in eliminating brake noise.

Finally, it’s essential to ensure that the entire braking system is clean. Dirt, debris, and grime can accumulate on the rotor and brake pads, leading to noise and decreased braking performance. Regular cleaning with a suitable solvent can help maintain the optimal functioning of your disc brakes and prevent squeaking. When adjusting the brake pads and calipers, always refer to the manufacturer’s instructions for your specific bicycle model, as techniques and specifications can vary.

| Adjustment Task | Tools Required | Expected Outcome |

|---|---|---|

| Caliper Alignment | Allen keys, Torque wrench | Caliper centered over rotor |

| Brake Pad Replacement | Brake pad spreader, Allen keys | Even brake pad wear, No squeaking |

| Cleaning Rotor and Pads | Clean cloth, Isopropyl alcohol | Clean, efficient braking system |

| Pad Position Adjustment | Allen keys, Screwdriver | Proper pad alignment, Reduced noise |

| Systematic Check-up | Inspection light, Cleaning tools | Overall optimized brake performance |

Adjusting brake pads and calipers is a meticulous process that, when done correctly, can greatly enhance your cycling experience by eliminating unwanted noise and improving brake efficiency. By following the steps outlined above and regularly maintaining your bicycle’s braking system, you can ensure a smoother and quieter ride. Remember, safety is paramount, so if you’re ever unsure about performing these adjustments yourself, don’t hesitate to seek professional assistance.

Each aspect of brake adjustment, from caliper alignment to pad replacement, plays a vital role in the overall performance of your bicycle’s braking system. Regular checks and maintenance not only prevent the annoying squeak of brakes but also prolong the lifespan of your bike’s components. Embrace these adjustments as part of your routine bicycle care to enjoy every ride to its fullest, free from the distraction of squeaking brakes.

Importance of Proper Brake Bedding

Understanding the importance of proper brake bedding is crucial for maintaining the performance and longevity of your bicycle disc brakes. Brake bedding refers to the process of conditioning the surface of your brake pads and the disc brake rotor. This procedure is paramount as it ensures that the surface of the brake pads is evenly deposited onto the rotor, resulting in a smoother and more consistent braking experience. Without proper bedding, your brakes may not only squeak annoyingly but could also suffer from reduced braking efficiency and potentially a shorter lifespan.

The process of brake bedding involves a series of controlled braking actions that allow the pad and rotor surfaces to mate optimally. This process generates a thin layer of brake pad material, known as the transfer layer, on the rotor. This layer is key to achieving the ideal friction performance necessary for effective stopping power. The absence of a properly formed transfer layer is often a primary cause of brake squeal. The high-frequency vibration that occurs between the brake pad and the rotor without this layer can lead to the unsettling noise that many cyclists encounter. Furthermore, improper bedding can result in uneven wear on both the brake pads and rotors, necessitating premature replacements and potentially compromising safety.

Moreover, a well-executed bedding-in process enhances the thermal capacity of your braking system, enabling it to perform reliably under various riding conditions, whether it’s a leisurely ride in the park or an intense downhill mountain biking session. It essentially prepares the brake system to handle the heat generated during braking without fading or losing effectiveness. This is particularly important for riders who demand a lot from their equipment in terms of performance and safety.

Steps to Proper Brake Bedding

Here are additional insights and context on ensuring a successful brake bedding process. The goal is to achieve a quiet, efficient braking system that inspires confidence across all riding conditions.

| Step | Action | Objective |

|---|---|---|

| 1 | Perform gentle stops from a low speed | Begin the process of transfer layer formation |

| 2 | Increase speed and apply firmer brakes | Evenly distribute the pad material onto the rotor |

| 3 | Allow brakes to cool down | Prevent overheating and ensure the layer sets properly |

| 4 | Repeat the process if necessary | Ensure a consistent and complete transfer layer |

| 5 | Test brakes in a safe area | Confirm the effectiveness and adjust if needed |

Correctly bedding in your bicycle disc brakes is not just about eliminating noise; it’s about optimizing the entire braking system for reliability, safety, and performance. By following the proper steps and understanding the significance of this process, cyclists can enjoy a better riding experience and prolong the life of their brake components.

Upgrading Your Brake Components

When it comes to enhancing the performance of your bicycle, especially concerning the efficiency of stopping, upgrading your brake components can play a pivotal role. One of the most straightforward approaches to mitigate the issue of squeaking disc brakes is to invest in higher-quality brake pads. Different materials can significantly affect both the longevity and the noise level of your braking system. For instance, organic pads might offer quieter operation, whereas metallic ones could provide better heat dissipation and durability under harsh conditions.

Another critical aspect to consider is the brake rotors. Upgrading to rotors that are designed to better handle heat and friction can make a substantial difference. The design and material of the rotor influence its ability to shed heat and resist warping, both of which are crucial for maintaining optimal performance and reducing noise. Additionally, ensuring that your brake system is compatible with the type of rotor you choose is essential for achieving the best results.

Lastly, don’t overlook the importance of regular maintenance and proper installation. Even the highest quality components can underperform if not correctly installed or if they are allowed to fall into disrepair. Regular cleaning and adjustment can also go a long way in keeping your brakes functioning quietly and efficiently.

| Component | Material Options | Benefits |

|---|---|---|

| Brake Pads | Organic, Metallic, Ceramic | Quieter operation, Better heat dissipation, Increased durability |

| Brake Rotors | Steel, Aluminum, Carbon | Improved heat management, Lighter weight, Enhanced longevity |

| Brake Calipers | Alloy, Steel, Carbon Fiber | Higher clamping force, Reduced weight, Better resistance to corrosion |

| Brake Lines | Rubber, Braided Stainless Steel | Increased durability, Better pressure handling, Enhanced performance |

| Brake Fluid | DOT 3, DOT 4, DOT 5.1 | Higher boiling point, Improved resistance to moisture absorption |

Further Insights on Upgrading Brake Components

Upgrading your bicycle’s brake components is not just about replacing old parts with new ones; it’s about enhancing your riding experience and safety. High-quality brake components ensure that your bike responds effectively when you need to stop, regardless of the conditions. This is crucial for both competitive cyclists and casual riders alike. By selecting the right materials and maintaining them properly, you can significantly reduce brake squeal, improve stopping power, and enjoy a smoother, more reliable ride.

In conclusion, addressing the squeaking of bicycle disc brakes by upgrading your brake components is an investment in both your bike’s performance and your safety. Considering the material, design, and compatibility of each component can lead to a quieter, more efficient braking system. Remember, regular maintenance is key to sustaining these benefits over time. By taking these steps, you can enjoy a more pleasant and reliable cycling experience.